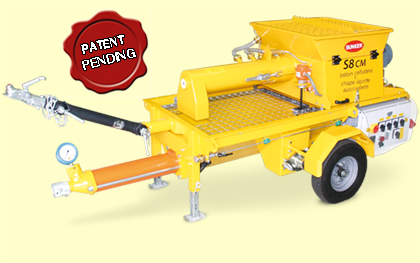

S8 CM Floor screed mixer-transporter - Description

S8 CM

Cellular concrete and self-levelling

Currently, normal mixers or spiral mixers are used for preparation of lightweight floor screeds.

The pumping of the screed happens subsequently in a separate screw pump placed close to the mixer.

With this system, the job cycle is discontinuous because it’s necessary to pump all the material in the mixer and then wait around 6-7 minutes for another mix to be ready and pumped.

In order to improve the job cycle, insure the homogeneity of the mixture in time, and avoid annoying blockages during pumping of the mixture, Bunker has designed and built the S8 CM, designed to mix and pump continuously:

- Lightweight screeds for thermal insulation floors

- Anhydride and cement-based self-levelling screeds

How the machine works:

The cement powder obtained in bags or from a silo is fed into the hopper of the continuous mixer.

In the mixing chamber the following are introduced simultaneously:

- The cement powder, through the spiral metering placed in the hopper of the continuous mixer

- The water in the appropriate quantity, via an electric pump mounted on machine

- The foam, in the correct amount, through the foam generator mounted on the machine

The materials are then quickly mixed up until they reach the desired consistency and density.

The mixture comes out from the mixing chamber and is discharged into the mixing / pumping hopper, where it is mixed again and pumped by the screw pump, through the rubber hoses, to point of installation.

For floor Screeding the above procedure guarantees…

- Absence of segregation

- Correct consistency

- Absence of lumps

- Pumping process free of annoying blockages

Compared to other machines presently on the market, S8 CM from Bunker ensures, apart from the continuous work cycle, the material receives a double mix:

First mixing takes place in the mixing chamber of the continuous mixer.

Second mixing takes place in the mixing and pumping hopper which contains a special mixer blade coupled to the screw pump. The second mixing avoids segretation of the mixture and blockages in the rubber hoses if / when pumping is stopped for short intervals or breaks.

Usually, in contract’s specifications, it is recommended to use lightweight screeds with cellular concrete with a density of 400 kg/m3. With S8 CM, to define the correct density of screed, and then the insulating capacity, simply measure the amount of foam fed into the mixing chamber. By changing the foam-cement ratio, a variable density is obtained from 300 to 600 kg/m3.