Tragen B200 pump for floor screed - Technical data

A modern machine with a stylish design that inspires safety

The experience gained over years of business and our constant effort in the ongoing improvement of our products have led to the creation of the B200 project: reducing the actuation power to just 2.2 kW without jeopardising performance was a challenge we faced with enthusiasm. See the results for yourselves.

|

|

|

|

The electrical panel is protected against knocks and tampering, and allows the operator to control the functions, indicating the status by means of indicator LEDs. |

|

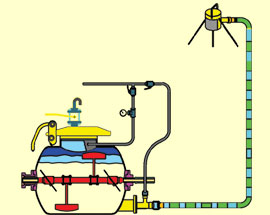

The tank 10 mm thick is designed and tested to resist wear and pressure, purpose designed for delivery piping of variable diameter and fitted with a protective grid that prevents the operator's hands from coming into contact with dangerous parts. When opened, the mixer blocks. |

The quick-closing lid with a balancing valve and a sturdy air release valve is also fitted with a safety device, which prevents it from being opened during operation. |

|

|

The tank interior is provided with a wear-resistant coating, the shaft is supported by special bearings and long-lasting perfectly airtight seals. The mixing blades are made of a wear-resistant alloy, and their 20 mm thickness ensures hundreds of working hours. |

How does it work?Tragen rapidly mixes the mix loaded manually or by means of a loading skip, then the flow of compressed air pushes it along the piping to the laying site. |

|

|

Mixing, a factor not to be underestimatedWith the diffusion of quick-drying screed, the perfect mixing of the binder with the aggregate must be guaranteed in order to obtain the desired result and the chemical combinations necessary to achieve low residual humidity after just a few hours. The agitator blades, their shape and arrangement are designed especially for this purpose. |

Technical data

| B200 E | B200 EB | ||

| Electric motor (single phase) | V | 230 - 50Hz | 203 - 50Hz |

|---|---|---|---|

| Power | kW | 2,2 | 2,2 |

| Vessel capacity | l | 200 | 200 |

| Skip capacity | l | 200 | |

| Compressor air delivery* (minimum) | l/min. | 2000 - 2500 | 2000 - 2500 |

| Working pressure | bar | 6 | 6 |

| Vessel outlet | Ø | 60 - 65 - 100 | 60 - 65 - 100 |

| Floor screed output** | m³/h | 1,5 - 2 | 2 - 2,5 |

| Max. pumpable granulometry*** | mm | 20 | 20 |

| Horizontal conveying distance | m | 70 - 80 | 70 - 80 |

| Vertical conveying distance | m | 30 - 40 | 30 - 40 |

| Dimensions L x W x H | cm | 110 x 160 x 150 | 110 x 242 x 140 x 207 **** |

| Weight | Kg | 560 | 650 |

* Compressor not included

** Depends on the air delivery of the compressor used

*** With Ø 100 hose

**** With skip upright