Tragen B250DC floor screed mixer-transporter - Technical data

The transporter of this generation

New features

This machine has to meet particular demands. It must deal with heavy duty work and work with any type of mixture, even dry types with high grain size mass. Since the beginning of the Tragen project Bunker has taken into consideration the consumers and the retailers. This attention to your needs has led to the development of new and interesting features which include: a new style compressor, a new diesel engine, a new cowling and a new modular structure which has allowed the addition of numerous optional features. Let's find out what they are.

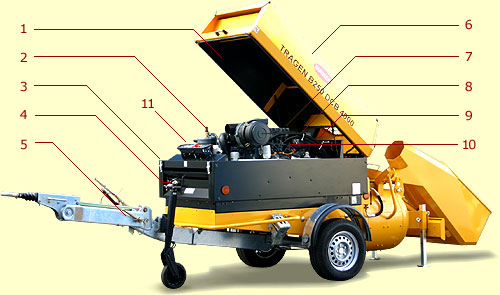

1 - The hood's large opening facilitates controls and maintenance.

2 - A new compressor element Atlas-Copco which reduces absorption power by 12% has been chosen specially for the new Tragen DC.

3 - A special varnishing process ensures maximum protectioon.

4 - Auxiliary valves allow the use of pneumatic tools and parts.

5 - An axle with torsion bars with oscillating arms guarantee maximum stability.

6 - Internal sound absorbent coating controls the noise of the machine to conform to regulation CEE 84/533.

The Tragen's low noise levels it can be used near hospitals, schools and residential areas.

7 - A new quiet and environment friendly Deutz engine has been used to guarantee reliabilty, tested by the manufacturer it meets the toughest needs.

8 - The engine and compressor are protected from dust and dirt by a single, two stage, high performance filter. The filter has an indicator which monitors blockage and obstruction and indicates the need to clean or replace the relevant parts.

9 - The fuel tank cistern ensures durability for a full job and guarantess maximum productivity.

10 - The automatic speed regulator constantly adapts the turning of the engine to the quantity of air required. This has many advantages: it saves energy, reduces fuel consumption and allows continuous air flow at a constant pressure.

11 - The controls are grouped together on one panel which is protected by another transparent panel, this guarantees safety and makes it easy to use.

The advantages of hydraulic drive

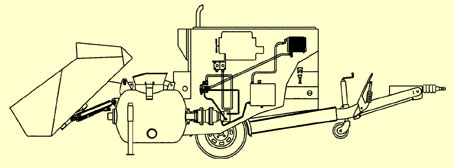

It is acknowledged that the use of oleodynamic drives means more control and less stress. It avoids using useless mechanisms such as joints, pulleys and belts, this guarantees increased safety and eliminates maintenance. With Tragen B250 DC the mixer, skip and scraping blade are all hydraulically driven... a definite advantage!

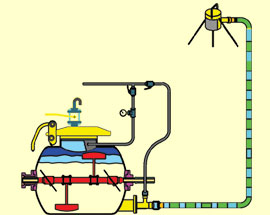

How does it work?The floor screed which is loaded either manually or using the skip is mixed quickly by the internal blades of the mixer barrel, subsequently the flow of compressed air pushes it through the tubing to the point of release. |

|

|

Mixing - not to be under estimatedWith the floor screed mixture left to dry quickly, a perfect mixture of inerts and binding agent must be guaranteed in order to achieve the best results and to have the fundamental chemical combination for low levels of humidity within a few hours. The form and number of agitator blades are studied for this reason. |

|

Compressor componentA new screw on, oil injection compressor component has been chosen specially for the Tragen B250 DC. This component produced by ATLAS-COPCO (world leader in the air compressor sector) has an asymetrical profile modified to emphasize its superb fundamental characteristics. |

|

The heart of the machine Unlike an electric engine to which we would pay little attention, the diesel engine is the heart of the whole system of this machine, that is why we chose a Deutz, in particular the latest model, the1011 (F3M1011F). The main feature of the new version is the cooling of the cylinders and cylinder heads with lubricating oil by a large cooler designed to maintain the engines temperature. This system reduces the machine's noise levels. The performance of the F3M1011F means the Tragen B250 DC is safely activated. |

|

Maintenance and supportTo ensure the Tragen meets your needs in terms of quality, performance and reliability it needs some attention. You will find that it is a fast and simple process. The diagonal opening of the cowling allows easy access to the machine. Bunker in Italy and abroad guarantees professional technical assistance. |

|

Protecting your investmentBunker conveyors resist the most diverse conditions. All their parts undergo sandblasting, varnishing and heat treatments. These processes ensure the best protection for your investment and mean it will keep its value. |

Meeting safety standardsThe vessel has been designed and tested to resist pressure and general wear and tear, it is prepared for hoses of different diameter and is fitted with a protective grill which once open blocks the mixer. The fast closing lid has a balanced spring and a robust vent valve this safety feature stops if opening during use. Inside the machine the mixer shaft is supported by special pads and durable, strong capacity washers. The mixing blades are anti wear and tear resistant. |

|

|

|

|

|

Technical data

| B250 DCB 2400 |

B250 DCB 4000 |

B250 DCB 5200 |

B250 DC 2400 |

B250 DC 4000 |

B250 DC 5200 |

||

| Diesel engine | Deutz | Deutz | Deutz | Deutz | Deutz | Deutz | |

|---|---|---|---|---|---|---|---|

| Model | F2M2011 | F3M2011F | F3M2011F | F2M2011 | F3M2011F | F3M2011F | |

| Power | kW | 21,6 | 32,5 | 36,0 | 21,6 | 32,5 | 36,0 |

| Compressor | Atlas Copco | Atlas Copco | Atlas Copco | Atlas Copco | Atlas Copco | Atlas Copco | |

| Air flow | l/min | 2400 | 4000 | 5200 | 2400 | 4000 | 5200 |

| Working Pressure | bar | 7 | 7 | 7 | 7 | 7 | 7 |

| Vessel capacity | l | 270 | 270 | 270 | 270 | 270 | 270 |

| Output | m³/h | 3 | 4 | 5 | 3 | 4 | 5 |

| Max granulometry | mm | 20 | 20 | 20 | 20 | 20 | 20 |

| Conveying distance | |||||||

| Horizontal* | m | 80 | 160 | 180 | 80 | 160 | 180 |

| Vertical* | m | 50 | 80 | 100 | 50 | 80 | 100 |

| Diameter vessel outlet | m | 60-65-100 | 60-65-100 | 60-65-100 | 60-65-100 | 60-65-100 | 60-65-100 |

| Size | |||||||

| Lenght | mm | 5590 | 5805 | 5805 | 4595 | 4810 | 4810 |

| Width | mm | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 |

| Height | mm | 1640 | 1640 | 1665 | 1640 | 1640 | 1665 |

| Height with loading skip up | mm | 2350 | 2350 | 2350 | |||

| Weight | Kg | 1590 | 1750 | 1786 | 1470 | 1630 | 1670 |

* Depending on material, consistency and hose diameter